SSI SCHAEFER unveils the SSI Pallet Roaming Shuttle, a new generation of autonomous shuttles dedicated to automating pallet storage in warehouses

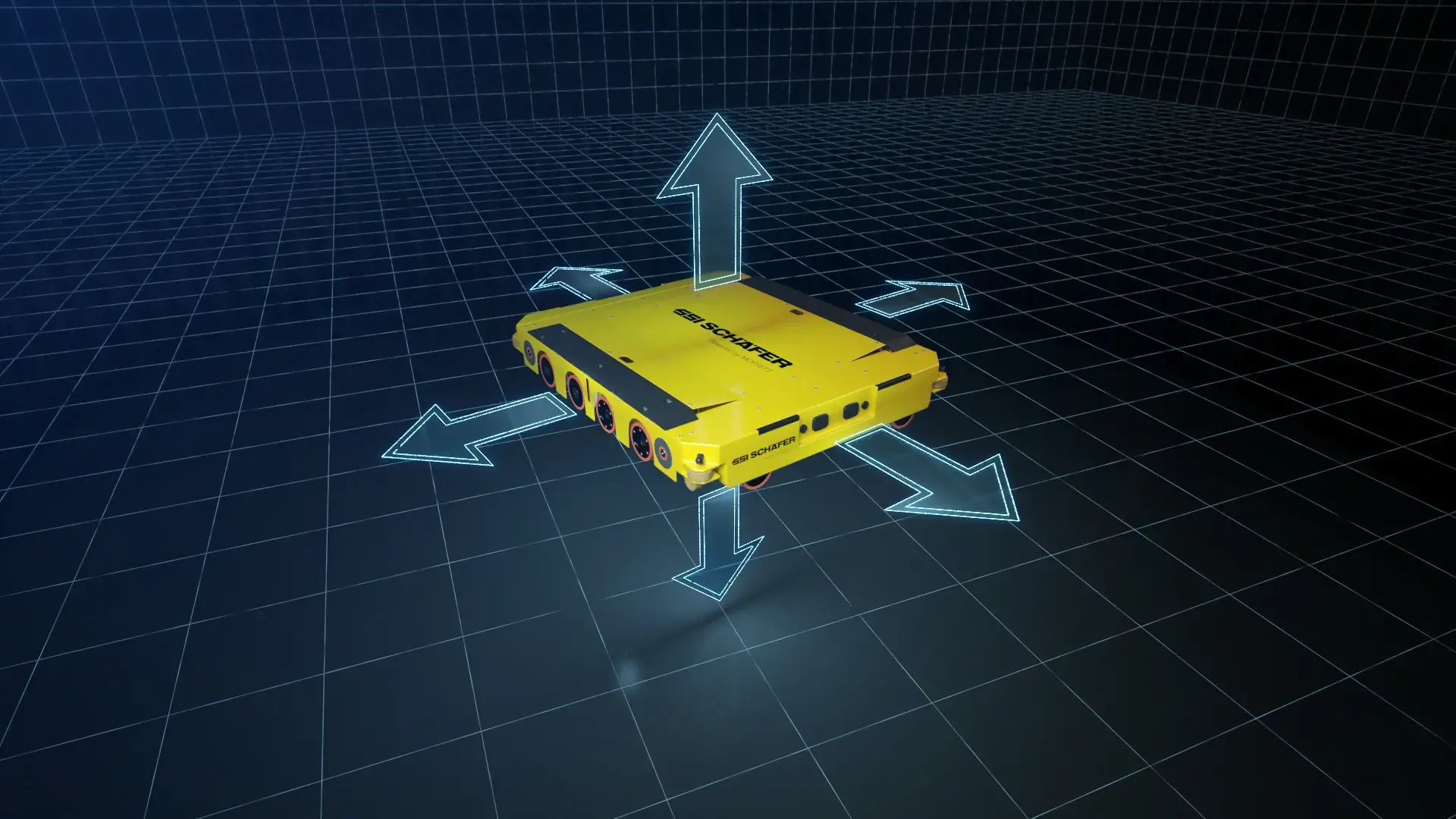

During its participation in the CFIA trade fair in Rennes, SSI SCHAEFER , a global player in intralogistics, announces the launch of the SSI Pallet Roaming Shuttle: a new generation 3D shuttle system designed to automate the storage and handling of pallets in warehouses. Intelligent, fast and scalable, this modular six - way system has been specifically developed to meet the logistical constraints of SMEs, particularly in complex or space-constrained environments.

SSI Schaefer is taking another step forward in intralogistics automation. At the CFIA food and beverage trade show, taking place from March 11 to 12 in Rennes, the global leader will present the SSI Pallet Roaming Shuttle: a compact and modular solution for the automated transport and storage of pallets in warehouses, capable of handling loads of up to 1.5 tons. The key advantage of this solution lies in its three-dimensional mobility. The shuttles can move horizontally, vertically, and horizontally, providing direct access to every storage location. This flexibility ensures a smooth, fast, and secure flow of pallets between the different levels of the warehouse.

Up to 65% more storage capacity

Another key advantage is the compact design of the SSI Pallet Roaming Shuttle. Combined with the absence of wide aisles, this allows for optimal use of available space, both in new warehouses and existing buildings. The result: an increase in storage capacity of up to 65% compared to traditional VNA (Very Narrow Aisle) solutions.

The solution has also been designed to adapt to a wide variety of configurations, including the most constrained environments: low-height warehouses, multi-depth installations or cold environments down to -25°C, while maintaining an average availability rate of 80% compared to ambient temperature operation.

Performance and energy efficiency

Operationally, the SSI Pallet Roaming Shuttle delivers high performance, with speeds reaching up to 1.8 m/s, ensuring optimized throughput and rapid handling cycles. Designed with eco-design principles in mind, the system incorporates automatic recharging and regenerative braking, contributing to a significant reduction in energy consumption. Equipped with smart sensors, it ensures reliable and safe operation, even in dimly lit or unlit environments, reducing lighting requirements and optimizing operating costs.

The system is managed by integrated software capable of monitoring the entire fleet of shuttles in real time. Operators also have remote access to key data: temperature, engine status, diagnostics, and unit operations. The SSI Pallet Roaming Shuttle interfaces with existing WMS and WCS systems on the market, ensuring seamless integration and continuous operation without disruption to logistics processes.

An innovation resulting from a partnership with Moffett Automation

The SSI Pallet Roaming Shuttle is the result of a strategic partnership between SSI SCHAEFER and Moffett Automation. It combines SSI SCHAEFER's expertise in global intralogistics with Moffett Automation's technological know-how in automated shuttle systems. This collaboration illustrates the two companies' commitment to developing high-performance, sustainable automation solutions tailored to the operational needs of logistics operators.

Main technical characteristics:

- Load capacity: up to 1,500 kg

- Operating temperature: -25°C to +50°C

- Speed: 1.4 to 1.8 m/s

- Battery: Lithium 100 Ah

- Battery life: 8 hours at room temperature / 6.6 hours in a refrigerated environment

- Communication: Mesh Wi-Fi network

SSI SCHAEFER teams at the CFIA Rennes trade fair, March 10, 11 and 12, 2026, stand 3-C01.

Dans la même catégorie

Parnass Transport uses the PTV Developer platform to create a 100% customized TMS

A solid partnership, solid logistics: SSI Schaefer builds a highly automated warehouse for CERP