Sparck Technologies receives a “Royal” title from the Netherlands

Sparck Technologies, a specialist in customized automated packaging systems, has been honored by His Majesty King Willem-Alexander with the prestigious "Royal" distinction. Kees Oosting, its CEO, received this title from Dr. A.A.M. Brok, King's Commissioner of the Province of Friesland.

The "Royal" honorary title is an exclusive recognition awarded to companies that, for at least a century, have distinguished themselves through an impeccable reputation, a solid organization, and a valuable contribution to society.

A History of Innovation

Founded in 1924 in Drachten, the Netherlands, under the name "HaDeWe," Sparck Technologies began with the invention of the first automated wooden clog production machine. The company later evolved into mailroom solutions before becoming a global leader in automated packaging systems. In 2014, it launched a fully automated packaging machine, marking its first steps into the growing e-commerce sector. Since then, more than 220 million custom-made packages have been produced using its machines.

A Global Presence

Today, Sparck Technologies operates in more than 15 countries in Europe and the United States, and employs 200 people. From its production site in Drachten, the company serves an international market seeking more environmentally friendly packaging, meeting end-consumer demand. Using 3D scanning technology to size, create, and label custom-made packaging without unnecessary vacuum, Sparck Technologies places innovation at the heart of its business. Its clients in France include leading players such as Cdiscount, King Jouet, Biosynex, and Valrhona.

Mr. Dr. A.A.M. Brok welcomed the designation: "Sparck Technologies is renowned for its innovation, technology, and progress—a strong, healthy, and forward-looking company with ambitions. This is something to be proud of. I am proud and grateful to announce that His Majesty the King has seen fit to bestow the company with the Royal designation."

CEO Kees Oosting expressed his pride at the recognition: "Receiving the Royal designation is a tremendous honor and a wonderful recognition of the hard work and dedication of our entire team. It reflects not only our rich history and innovative capacity, but also our commitment to sustainability and social responsibility. Our focus on automation has always driven us forward, and the fact that we can now feature a crown in our logo means a lot to us."

Dans la même catégorie

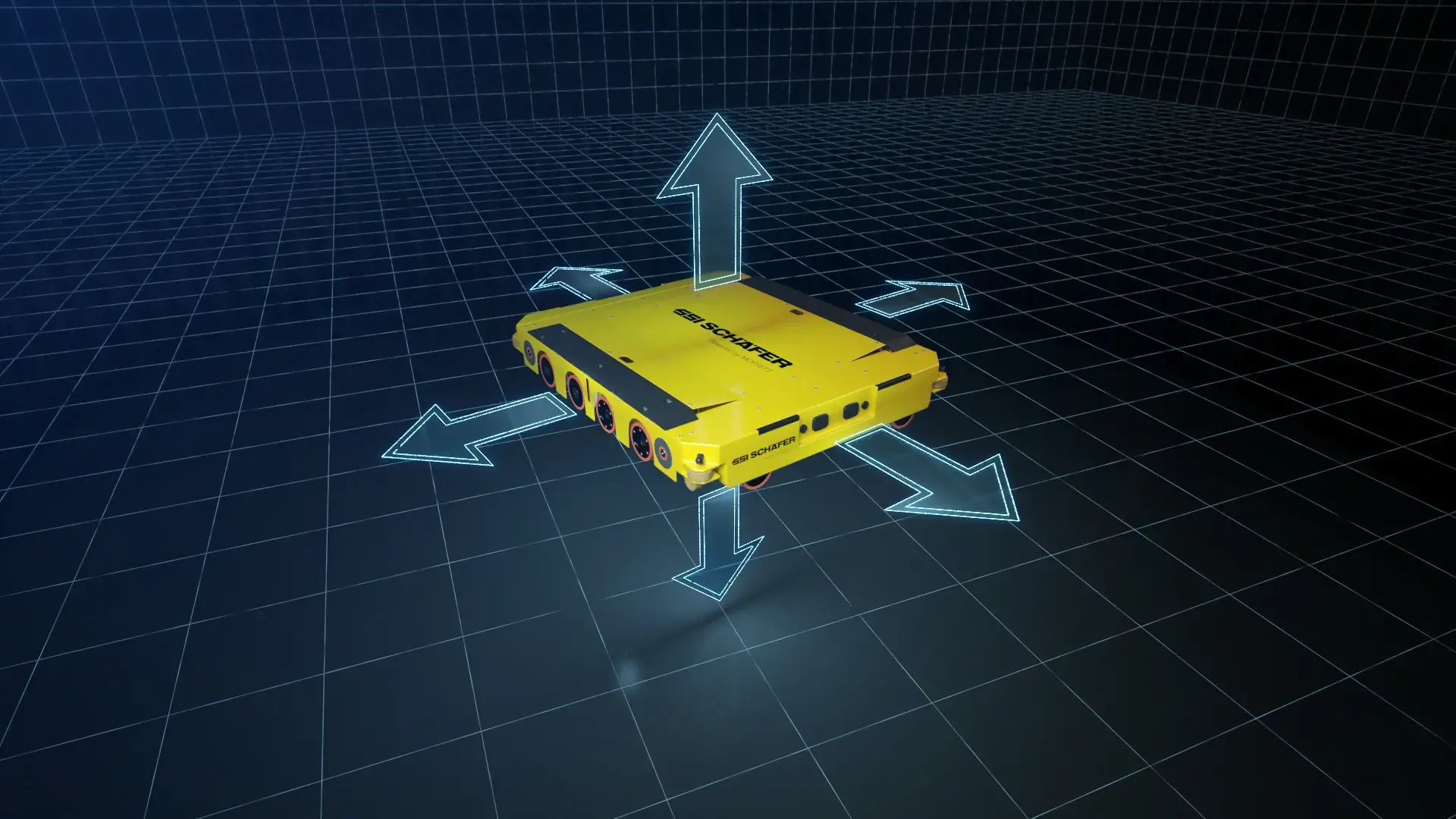

SSI SCHAEFER unveils the SSI Pallet Roaming Shuttle, a new generation of autonomous shuttles dedicated to automating pallet storage in warehouses

Parnass Transport uses the PTV Developer platform to create a 100% customized TMS