UVOTec expands its offering with Destuff-it, Gorbel's mobile and ergonomic conveyor

UVOTec, a specialist in the supply of handling solutions, has entered into a distribution agreement for France and Benelux with American manufacturer Gorbel. This agreement enables UVOTec to expand its portfolio with the Destuff-it container unloading system : a powerful, mobile, and ergonomic battery-powered belt conveyor.

Gorbel is a leading family-owned company in the United States, headquartered in Victor, New York. The company employs more than 800 people worldwide and has six manufacturing facilities, including two dedicated to the production of Destuff-it. Its customers include leading industrial and e-commerce companies such as Staples, FedEx , and French equipment manufacturer Michelin.

A win-win agreement

The bilateral agreement between UVOTec and Gorbel aims to support their respective growth. By entrusting UVOTec with the distribution of its Destuff-it system in France and Benelux, Gorbel is joining forces with a trusted partner, active for 25 years in the marketing and installation of warehouse conveyor systems. This collaboration will allow Gorbel to strengthen its presence in Europe , a market with high potential, particularly in France where employee safety is a priority. For UVOTec, this collaboration with Gorbel enriches its catalog by integrating a system recognized and tested by the biggest players in the sector. Nearly 3,000 installations have been commissioned since 2015.

Up to 1800 parcels/hour

The result of Gorbel's technological know-how, the Destuff-it is a motorized , ergonomic and mobile conveyor, designed to simplify the unloading of containers and optimize organization within the warehouse. The machine is battery-powered and can therefore be easily moved from one dock to another, providing more floor space and greater ease of work. Another major advantage of the system: its fully articulated feed belt significantly reduces operator effort, particularly when handling heavy loads, and further improves working comfort. Carrying goods is practically eliminated. Finally, thanks to its intuitive interface, the Destuff-it platform constantly adapts to ensure optimal and smooth operation. With an average throughput of 900 parcels/hour, which can reach 1,800 parcels/hour depending on the goods, the Destuff-it increases productivity and reduces processing costs. by 50%.

“With Destuff -it , our customers in France and Benelux now have a new system that simplifies their unloading processes while improving the safety and comfort of their teams. It helps optimize logistics flows and simultaneously strengthens the competitiveness of companies in a sector where every productivity gain counts" testifies Laurent Uvo , director of UVOTec .

For Gorbel , this collaboration is an opportunity: "We are delighted to collaborate with UVOTec, whose expertise and knowledge of the European market are major assets. The distribution of Destuff-it in France and Benelux allows us to offer an innovative solution to logistics players who wish to improve the ergonomics and efficiency of their operations" underlines Rob Beightol , Marketing Director of Gorbel .

Dans la même catégorie

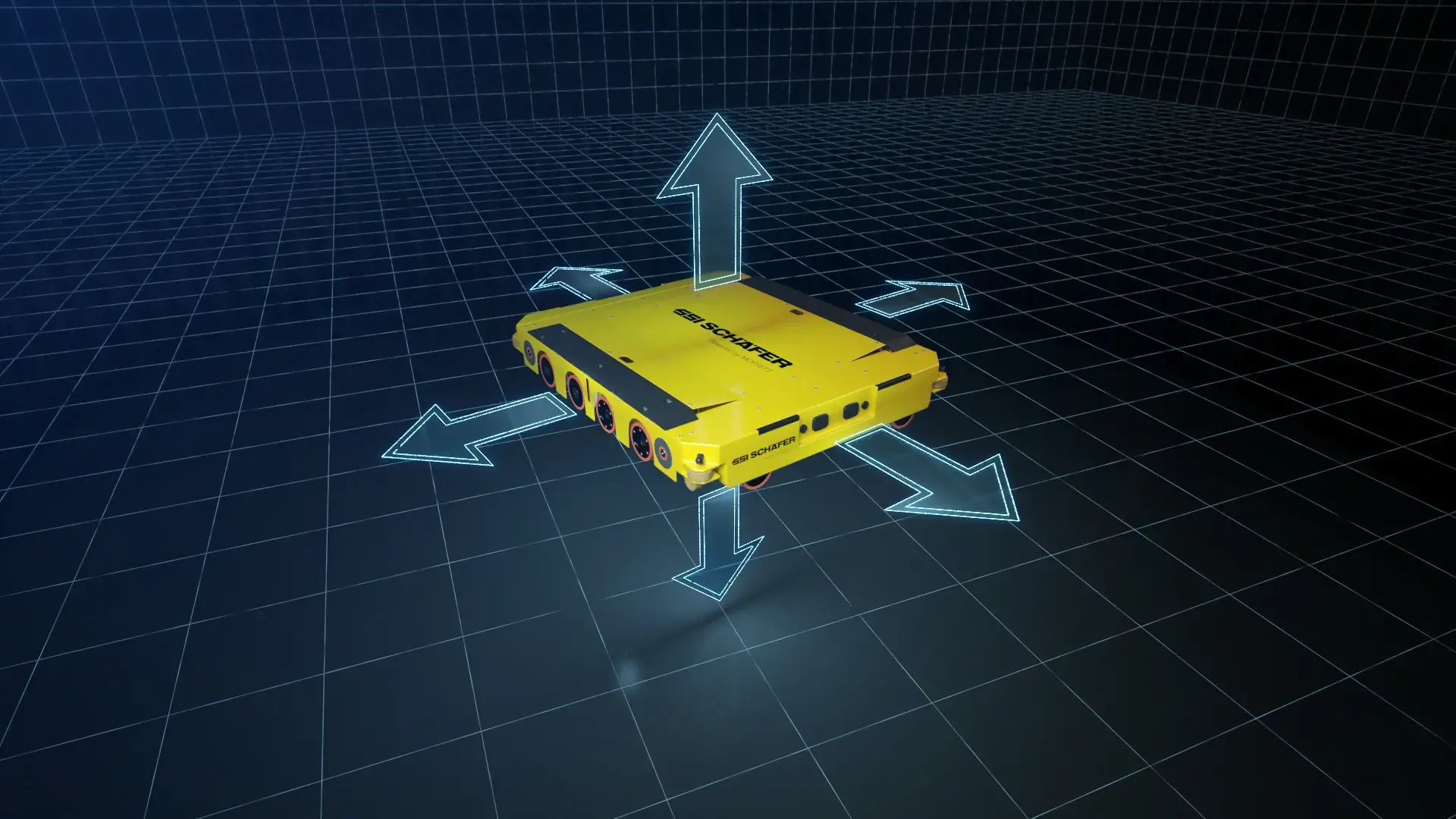

SSI SCHAEFER unveils the SSI Pallet Roaming Shuttle, a new generation of autonomous shuttles dedicated to automating pallet storage in warehouses

Parnass Transport uses the PTV Developer platform to create a 100% customized TMS