With 4 million parcels, Aroma-Zone strengthens its logistics with Boa Concept

France 's second favorite brand (OC&C) in 2025 and best e-commerce site (FEVAD), Aroma-Zone, the French leader in skincare, well-being, and natural beauty, continues its growth with a strong ambition: to ship 4 million packages by the end of the year. To meet this logistical challenge, the brand is relying on nearly ten years of collaboration with Boa Concept, a specialist in intelligent automation.

Located in Châteauneuf-de-Gadagne (Vaucluse), the Aroma-Zone logistics site has progressed through successive stages of automation since 2016, in partnership with Boa Concept. Initially, picking was entirely manual, but in the face of rapid growth, automation has become essential to increase productivity and improve working conditions for operators. "Our operations relied on paper and pencil," comments Laurent Lucasson, Director of Operations. "Boa Concept supported us in this essential transition." In 2024, Aroma-Zone shipped 3 million packages, and is targeting 4 million this year. Its logistics warehouse supplies both online orders and the 27 physical stores.

A long-term logistics partnership

In 2016, an initial study conducted with Boa Concept enabled automation solutions to be adapted to the building's layout. Automatic launching machines were installed, followed by a package height reduction system, integrated and connected to the Boa Concept system. In 2018, the implementation of warehouse management software (WMS) interfaced with the Boa system optimized order preparation. Three years later, a new phase accelerated shipping rates, doubling the number of automatic sorting lanes for faster and more efficient shipping.

Automation designed for customer experience

Automation plays a key role in the packaging process. Five machines interfaced with the Boa line ensure carton launch, while an automatic document deposit system personalizes shipments to strengthen customer relations. A weighing control ensures package compliance and reduces preparation errors. Four machines adjust carton height for optimized closure, improving product safety and reducing transport costs. Supervision and control are centralized via the Boa Drive WCS, offering unified equipment management, 360° monitoring, and automatic error detection. A Boa conveyor line streamlines package flow, while the shipping area relies on 20 carrier sorting lanes, ensuring fast and reliable routing. Thanks to Boa Concept modular solutions, Aroma-Zone has reduced preparation times and errors, while optimizing package volume. Result: the height of the boxes can be reduced from 10 cm to just 2 cm, increasing truck loading capacity by 30% and reducing logistics costs.

A strong commitment to responsible logistics

The automation adopted by Aroma-Zone is part of an ambitious CSR approach, combining performance with social and environmental responsibility. Well received by the teams, it has improved working conditions by reducing repetitive movements and integrating specific support. On the environmental side, packages are free of over-packaging, wedged with recycled paper, and printing uses vegetable-based inks. The silent and energy-efficient conveyors are equipped with presence detectors and can be reused during site changes. All Aroma-Zone sites now operate 100% on green energy, and a self-consumption project aims for 50% energy independence, notably thanks to a hydroelectric initiative in partnership with ADEME, exploiting a branch of the river near the logistics site.

Increased customer satisfaction

Thanks to these advances, Aroma-Zone has strengthened its commitment to its customers. Its NPS score exceeds 70 points , reflecting consumers' commitment to the quality of service and the brand's values. "Our customers are very committed, and so are we, in order to always be consistent with our ecological commitments," emphasizes Laurent Lucasson. " Automation is not synonymous with dehumanization: our teams remain at the heart of the system, and personalization is a priority."

Aroma-Zone continues its development by continuing the automation of picking and optimizing the preparation of e-commerce orders , to accelerate and streamline the entire logistics process. The optimization of picking locations is under study, with the integration of artificial intelligence to adapt flows in real time. At each stage of its evolution, for nearly 10 years, Boa Concept has been able to meet the requirements of performance, customization and reliability, supporting Aroma-Zone in its quest for operational excellence, constant innovation and environmental responsibility.

Dans la même catégorie

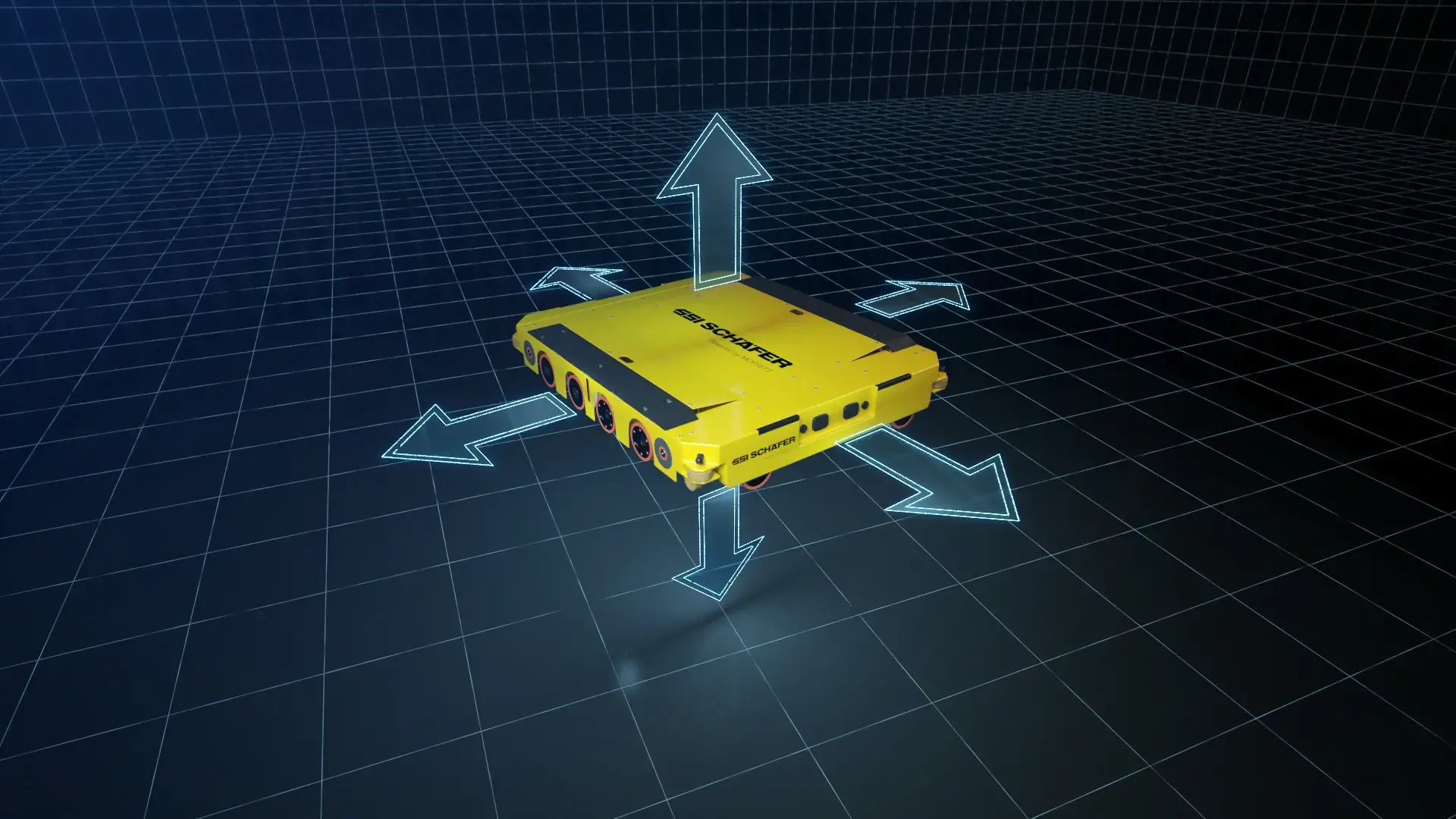

SSI SCHAEFER unveils the SSI Pallet Roaming Shuttle, a new generation of autonomous shuttles dedicated to automating pallet storage in warehouses

Parnass Transport uses the PTV Developer platform to create a 100% customized TMS